TRAILER MOUNTED LIGHT TOWERS

The HILITE Light Towers have been designed after consultation with the hire companies, their clients and the mining industry using readily available components and materials for ease of repair and low cost of maintenance.

The HILITE Light Towers have been designed after consultation with the hire companies, their clients and the mining industry using readily available components and materials for ease of repair and low cost of maintenance.The HILITE range of lighting towers has a proven track record with there extensive use throughout construction sites in Indonesia and various site applications throughout Australia. In fact, the very first unit built in 1992 is still in use today in the hire industry.

With the unit's durability and reliability, the HILITE range keeps attributing to its own success. It has the history of a proven track star in its field.

Features

We have an extensive range of portable lighting towers, designed for mining applications, engineering construction sites, or any situation where high intensity portable lighting is required.

Some features of our lighting towers include:

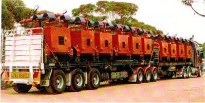

Compact for easy & cost effective transportation

Our attention to detail and application of clever ideas has resulted in a compact and easily transported lighting tower.

The 4000 and 6000 watt units allow for six units to be transported at one time on a flat top semi-trailer (40 foot,) or sea container.

Transport of 10 units at one time is possible on a B-Double truck.

This ease of transport minimizes transportation costs. Resulting in more efficient use of your transport resources.

Options - General

Machines can be tailored to suit your individual specifications, such as different motors, Gensets, etc. These include, but not limited to:

Option - Lights

We recommend the use Sylvania Metal Halide “Brightline” light-heads (although you may choose alternatives, if you require).

|

Safety

Mechanical — the unit is fitted with outriggers for unit stability and safety. Both wheel guards are fitted with non-slip tape and reflectors. The ram is fitted with a safety locking mechanism incorporating a protection guard.

Mechanical — the unit is fitted with outriggers for unit stability and safety. Both wheel guards are fitted with non-slip tape and reflectors. The ram is fitted with a safety locking mechanism incorporating a protection guard.All warning and safety signage is fitted with etched labels and not adhesive decals.

The front, weight bearing, jockey wheel is cast iron for extended life and easy of handling.

Electrical — the unit comes in two electrical configurations, mine spec unit or a non-mine spec unit.

The non-mine specification unit is fitted with earth leakage protection for circuits and molded plastic enclosures.

The mine specification unit is fitted with earth leakage protection for circuits within a stainless steel enclosures. The mine specification unit complies with the following standards:

How Does It Work

Operation of the units is simple and easily understood, making it ideal for the hire industry where each day a different person may be using the equipment. Simplicity means lower risk of damage to the unit from misuse.

Clearly labeled buttons and gauges also aid simplicity of use.

Very little damage can be done to the unit by operator’s misuse. We have included an automatic RAM retraction system for added safety and simplicity.

Non-Mine Specification Control Panel

|

Mine Specification Control Panel

|